- Sales

- Shop Online

- Art Supplies

- Baking Supplies

- Beads & Jewelry

- Crafts and Hobby

- DIY Decor

- Floral & Greenery

- Branches

- Decorative Elements

- Florals

- GarlandsLife like floral garlands and vines add to any home décor project indoors or outdoors. Give your home, party, or patio space a long lasting look and a ambiance of color using one of Craft Warehouse’s realistic-looking and affordable garlands.

- Plumes

- Succulents

- Floral Supplies

- Swags

- Wedding & Events

- Wreaths

- Gifts

- Home Décor & Framing

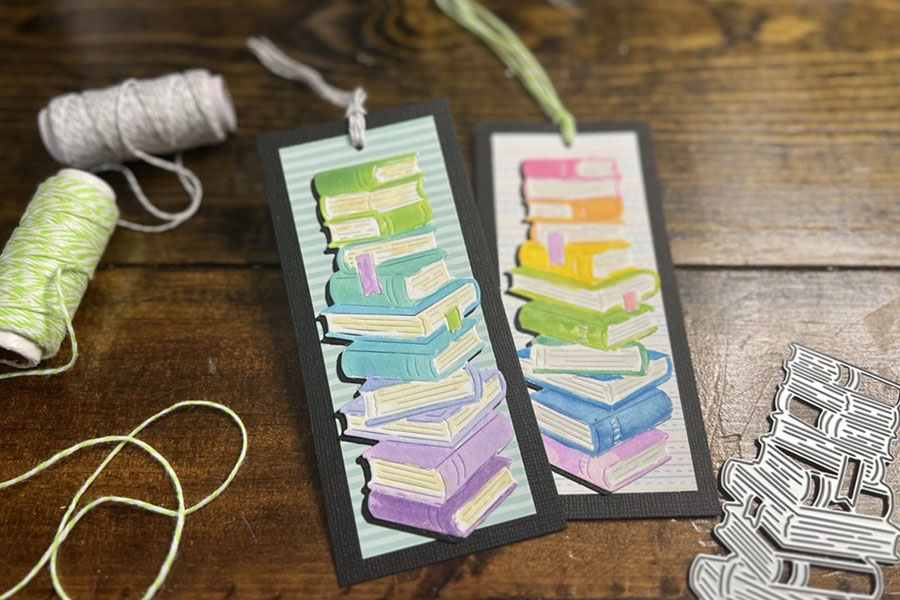

- PaperCraft

- Picture Framing

- Quilting Fabric & Sewing

- Sewing Storage

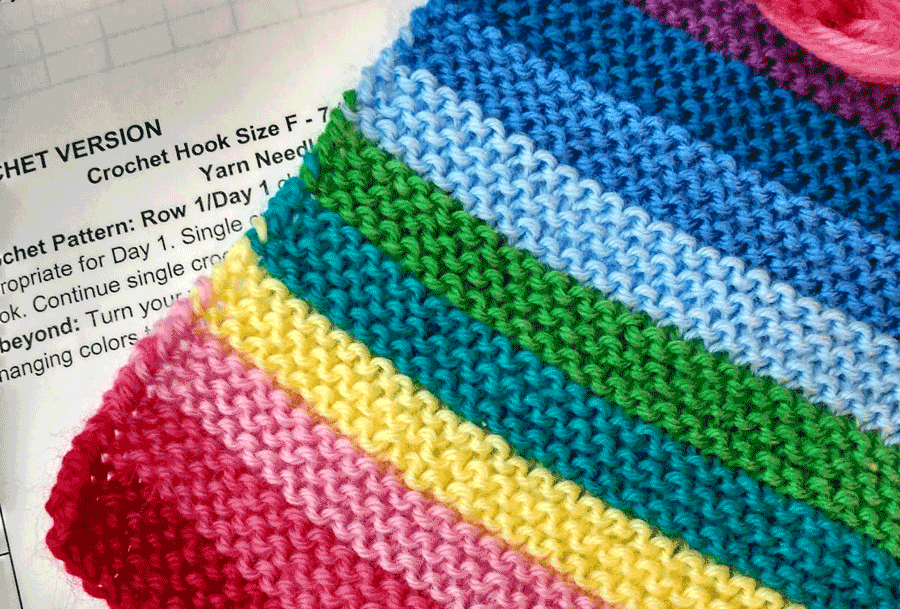

- Yarn & Needlework

- Events

- Create Blog

- Custom Picture Framing

- Store Locations

- Purchase a Gift Card

- About Us

- Contact Us

Subscribe to our Newsletter

Be the first to learn about Sales and Special Events. We’ll only send you the good stuff, no spam.*

Craft Warehouse focuses on providing quality components and supplies that the customer can easily transform to showcase their personal style.

Store Events

© Copyright | Craft Warehouse All Rights Reserved | beMORR Multimedia Design

Limited Time Coupon

Find That Perfect Gift and Save!

25% OFF

Any One Item

Coupon valid off regular, white-tagged prices. Coupon cannot be used for gift cards, custom picture framing, classes or special orders. Limited to stock on hand. One coupon per customer per day. Cannot be combined with any other coupon or discount. Excludes Cricut EasyPress, Gemini Hot FOILPRESS, Switch and Cutterpillar Glow products. Digital coupons from smart phones or printed coupons from digital communications are accepted. Exclusions subject to change. Valid December 14th to December 25th, 2023.

Some exclusions apply. Valid Dec. 14th to Dec. 25th, 2023.

In-Store or Online Use Code: GIFT25